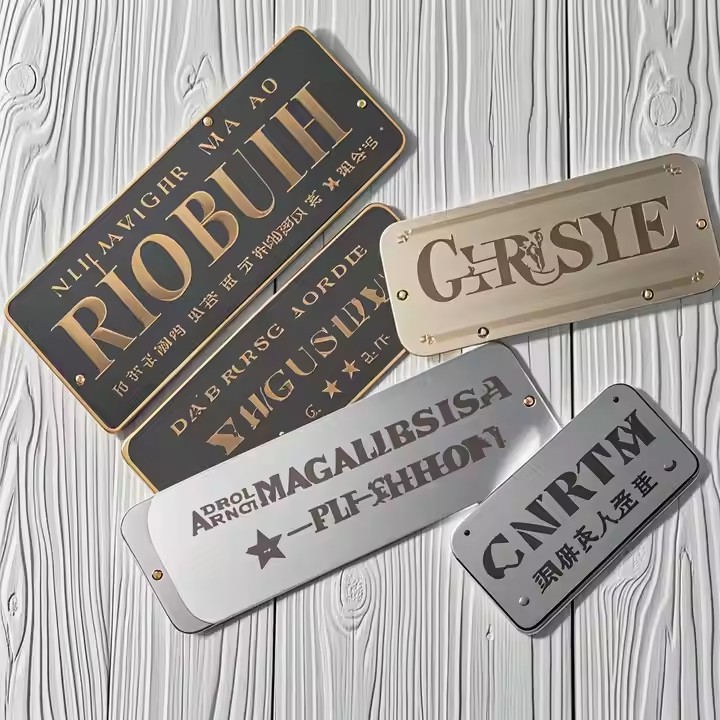

The Perfect Match of Luxury Packaging and Brass Labels

The Perfect Match of Luxury Packaging and Brass Labels In the world of luxury packaging, every detail matters. From the choice of materials to design elements, the packaging serves as an essential extension of a brand’s identity and value. Brass labels have emerged as a perfect match for luxury packaging, offering unmatched elegance, durability, and customization options that help brands stand out in competitive markets. 1. Elegant Aesthetic Appeal Brass labels feature a rich, warm golden hue that naturally conveys…

Surface Treatments for Brass Labels: Polishing, Sandblasting, Nickel Plating

Surface Treatments for Brass Labels: Polishing, Sandblasting, Nickel Plating Brass labels are prized for their durability and elegant appearance. To maximize their performance and aesthetic appeal, various surface treatment techniques are applied during production. Polishing, sandblasting, and nickel plating are three common and effective treatments that improve the final quality of brass labels. Understanding these methods helps in selecting the right finish for specific applications. 1. Polishing Polishing is the process of smoothing the brass surface to achieve a shiny…

Detailed Explanation of Stamping and Embossing for Brass Labels

Detailed Explanation of Stamping and Embossing for Brass Labels Stamping and embossing are two essential manufacturing techniques used to enhance the functionality and aesthetic appeal of brass labels. These processes add texture, depth, and durability, making brass labels stand out in both industrial and decorative applications. Understanding these techniques helps in appreciating the craftsmanship and design possibilities of brass labels. What is Stamping? Stamping is a process where a metal sheet, such as brass, is placed between a die and…

Complete Production Process of Brass Labels

Complete Production Process of Brass Labels Brass labels are valued for their durability, elegance, and customization potential. Producing high-quality brass labels involves a series of precise and carefully controlled manufacturing steps. Understanding the complete production process helps customers appreciate the craftsmanship and technology behind these premium metal labels. 1. Material Selection The production begins with selecting high-grade brass sheets or coils, typically composed of copper and zinc. The specific brass alloy and thickness are chosen based on the label’s intended…

Why Choose Brass for Labels? Analysis of Its Application Value

Why Choose Brass for Labels? Analysis of Its Application Value Choosing the right material for labels is crucial to ensure durability, brand representation, and functionality. Brass, a metal alloy primarily composed of copper and zinc, stands out as a superior choice for labels across various industries. This article explores the application value of brass for labels and why it continues to be favored by manufacturers, wholesalers, and end users alike. 1. Outstanding Durability Brass is highly resistant to corrosion, wear,…