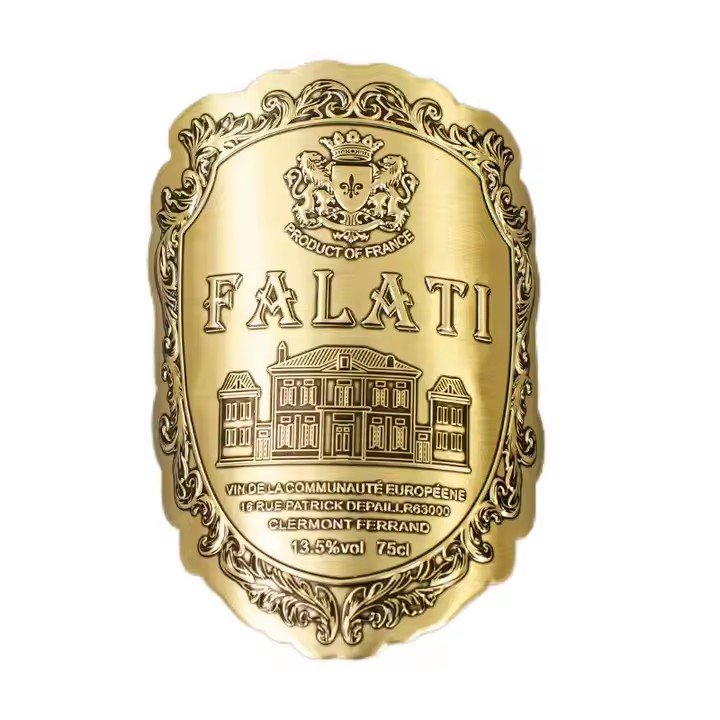

Surface Treatments for Aluminum Labels: Anodizing, Sandblasting, Polishing

Surface Treatments for Aluminum Labels: Anodizing, Sandblasting, Polishing Aluminum labels are widely used across industries due to their durability, lightweight nature, and excellent corrosion resistance. However, to maximize their performance and aesthetic appeal, surface treatments play a critical role. This article highlights three popular surface treatment methods for aluminum labels: anodizing, sandblasting, and polishing. 1. Anodizing Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum surfaces. This treatment significantly improves corrosion resistance, surface hardness, and wear…

Screen Printing vs Digital Printing for Aluminum Labels: Which Is Right for You?

Screen Printing vs Digital Printing for Aluminum Labels: Which Is Right for You? When producing aluminum labels, the printing method you choose plays a crucial role in determining the label’s quality, durability, and cost-effectiveness. Two of the most common printing techniques are screen printing and digital printing. Each has unique advantages and considerations. This article will help you understand their differences and decide which is best suited for your aluminum label projects. 1. What is Screen Printing? Screen printing involves…

Application of Laser Etching Technology in Aluminum Labels

Application of Laser Etching Technology in Aluminum Labels Laser etching technology has revolutionized the way aluminum labels are produced, offering unparalleled precision, durability, and flexibility. This technique uses a focused laser beam to permanently mark the aluminum surface, creating detailed and high-resolution designs that withstand harsh environments. Here’s an overview of how laser etching is applied in aluminum label production and its key benefits. 1. What is Laser Etching? Laser etching involves using a high-powered laser to remove a thin…

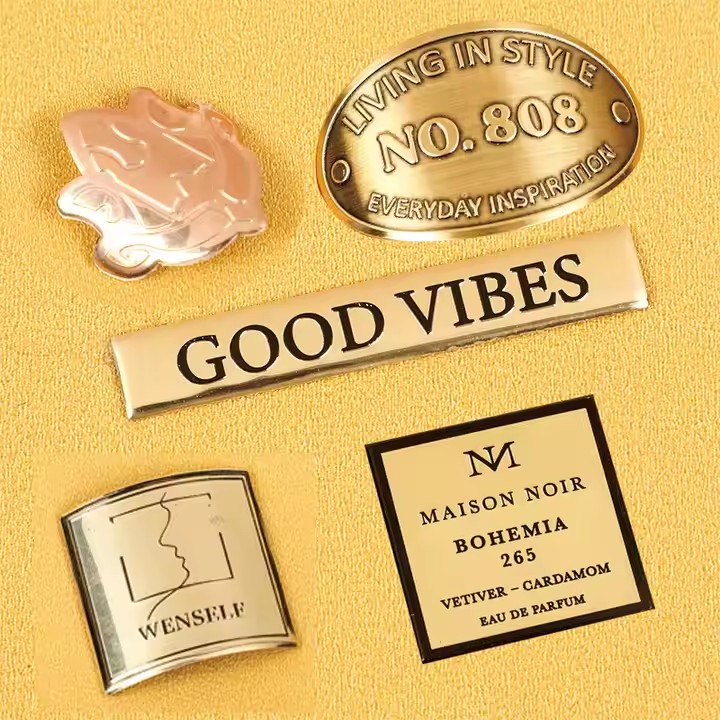

Step-by-Step Aluminum Label Production Process

Step-by-Step Aluminum Label Production Process Aluminum labels are widely used across various industries due to their durability, corrosion resistance, and customization capabilities. Understanding the production process can help manufacturers and clients ensure the quality and suitability of their aluminum labels. Here’s a detailed step-by-step guide on how aluminum labels are produced: 1. Raw Material Selection The production starts with selecting high-quality aluminum sheets or coils. The thickness and grade of aluminum depend on the intended use of the label. Typically,…

Durability of Aluminum Labels: Corrosion Resistance, Heat Resistance & More

Durability of Aluminum Labels: Corrosion Resistance, Heat Resistance & More Aluminum labels are renowned for their outstanding durability, making them a preferred choice in many industries requiring long-lasting and reliable identification solutions. This blog explores the key durability features of aluminum labels, including corrosion resistance, heat resistance, and additional factors that contribute to their robustness. 1. Corrosion Resistance One of the most significant advantages of aluminum labels is their natural corrosion resistance. Aluminum forms a thin oxide layer on its…