Common Materials for Embossed Metal Labels and Their Performance Comparison

Introduction

Embossed metal labels are widely used across industries due to their durability and distinctive appearance. However, the performance and suitability of these labels largely depend on the materials chosen. This article explores the common metals used for embossed labels and compares their key characteristics to help manufacturers and buyers make informed decisions.

1. Aluminum

Aluminum is a lightweight, corrosion-resistant metal often used for embossed labels. It offers good durability and is easy to emboss, making it suitable for both indoor and outdoor applications.

-

Advantages: Lightweight, excellent corrosion resistance, cost-effective, easy to customize

-

Disadvantages: Less impact resistant compared to steel or brass

-

Typical Uses: Industrial equipment, electrical panels, signage

2. Brass

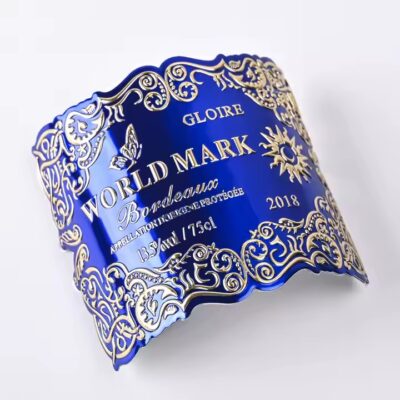

Brass is an alloy of copper and zinc known for its attractive gold-like appearance. It is durable and offers excellent corrosion resistance, especially in non-acidic environments.

-

Advantages: Aesthetic appeal, strong and durable, good corrosion resistance

-

Disadvantages: Higher cost, can tarnish over time without proper coating

-

Typical Uses: Luxury branding, nameplates, decorative tags

3. Stainless Steel

Stainless steel is renowned for its superior strength and corrosion resistance. It is heavier than aluminum but offers excellent longevity even in harsh environments.

-

Advantages: Highly durable, corrosion and heat resistant, maintains appearance over time

-

Disadvantages: More expensive, heavier, more difficult to emboss

-

Typical Uses: Medical equipment, automotive parts, outdoor industrial labels

4. Copper

Copper has excellent conductivity and an attractive reddish tone. While softer than stainless steel, it provides good embossing results and moderate corrosion resistance.

-

Advantages: Attractive appearance, good embossing detail, antimicrobial properties

-

Disadvantages: Prone to tarnishing and oxidation, requires protective coatings

-

Typical Uses: Specialty applications, electronic components, decorative labels

Performance Comparison Summary

| Material | Corrosion Resistance | Durability | Cost | Weight | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | High | Moderate | Low | Lightweight | Industrial, signage |

| Brass | Moderate to High | High | Medium to High | Medium | Luxury branding, decorative tags |

| Stainless Steel | Very High | Very High | High | Heavy | Medical, automotive, harsh environments |

| Copper | Moderate | Moderate | Medium | Medium | Specialty, electronics, decorative |

Conclusion

Choosing the right material for embossed metal labels depends on the specific needs of the application, including environmental exposure, aesthetic requirements, and budget constraints. Aluminum offers a cost-effective, corrosion-resistant option for general use, while stainless steel excels in durability and harsh conditions. Brass and copper provide premium looks for branding and decorative uses. Understanding these differences helps ensure optimal performance and longevity of your embossed metal labels.