Differences Between Industrial Metal Labels and Regular Metal Labels

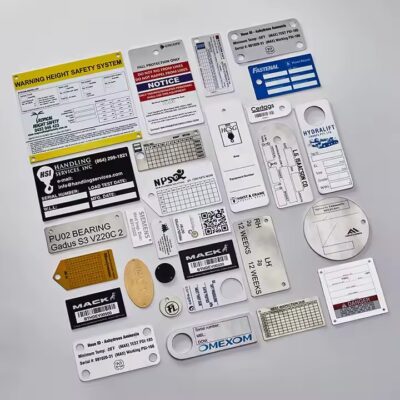

Metal labels are widely used across many industries for identification, branding, and tracking purposes. However, not all metal labels are created equal. Industrial metal labels and regular metal labels serve different needs and environments, and understanding their differences can help you choose the right labeling solution for your application.

Definition and Usage

-

Industrial Metal Labels are specifically designed for use in harsh, demanding industrial environments. They are engineered to withstand extreme conditions such as high temperatures, chemical exposure, abrasion, and corrosion. These labels are commonly found in manufacturing plants, automotive, aerospace, and heavy machinery industries.

-

Regular Metal Labels typically refer to metal tags or plates used in less demanding environments, such as consumer products, decorative purposes, signage, or general identification. They may not have the same level of resistance to harsh conditions.

Material Composition

Industrial metal labels are usually made from high-grade materials such as stainless steel, anodized aluminum, or brass, chosen for their strength and resistance to corrosion and wear. Regular metal labels may use similar materials but often in lower grades or without specialized treatments.

Durability and Environmental Resistance

-

Industrial metal labels are designed for maximum durability, offering resistance to:

-

Extreme temperatures

-

Chemical and solvent exposure

-

Mechanical abrasion and impact

-

UV radiation and moisture

-

-

Regular metal labels provide adequate durability for everyday use but may degrade or lose legibility when exposed to harsh environments.

Customization and Marking Methods

Industrial metal labels often require precision engraving, laser etching, or chemical etching to ensure permanent and highly legible markings. They can be customized to meet strict regulatory standards and specific industrial requirements.

Regular metal labels may use simpler printing or stamping methods suitable for less demanding conditions, and customization may focus more on aesthetic appeal than durability.

Application Examples

| Industrial Metal Labels | Regular Metal Labels |

|---|---|

| Equipment identification in factories | Product branding on consumer electronics |

| Asset tracking in automotive manufacturing | Nameplates and decorative signage |

| Safety and compliance tags in aerospace | General labeling on appliances |

Cost Considerations

Due to their enhanced materials and manufacturing processes, industrial metal labels generally come at a higher cost compared to regular metal labels. However, their long-term performance and reliability often justify the investment in industrial settings.

Conclusion

The choice between industrial metal labels and regular metal labels depends largely on the application environment and performance requirements. If your labeling needs involve exposure to tough conditions such as extreme heat, chemicals, or mechanical wear, industrial metal labels are the superior option. For less demanding uses, regular metal labels may suffice, offering a more economical solution.

Understanding these differences ensures you select the right label type, helping improve asset management, safety compliance, and brand representation.