Main Materials and Performance Characteristics of Metal Adhesive Labels

Metal adhesive labels are widely used in industries requiring durable and high-quality identification solutions. The performance and reliability of these labels largely depend on the materials used in their construction. Understanding the main materials and their characteristics is essential for selecting the right metal adhesive label for your application.

Main Materials Used in Metal Adhesive Labels

-

Aluminum:

Aluminum is a popular choice due to its lightweight nature, corrosion resistance, and cost-effectiveness. It offers excellent durability for indoor and outdoor applications and can be easily anodized or printed on for enhanced aesthetics and protection. -

Stainless Steel:

Stainless steel labels provide superior strength and corrosion resistance, especially in harsh environments such as chemical plants or marine settings. They are highly resistant to abrasion and maintain legibility under extreme conditions. -

Brass:

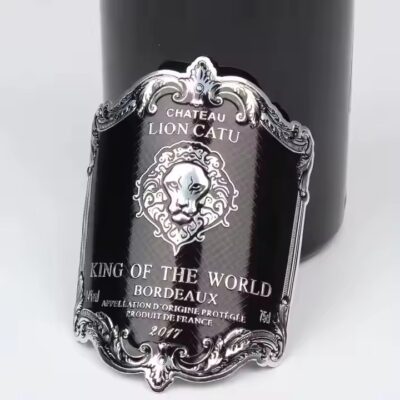

Brass offers a distinctive, premium look with good corrosion resistance and moderate durability. It is often used in decorative applications or where a classic metallic finish is desired. -

Copper:

Copper metal labels are less common but valued for their conductivity and unique aesthetic. They can be used in specialized industrial applications or decorative branding. -

Adhesive Backing:

The adhesive layer is critical for ensuring strong attachment to various surfaces. Common adhesives include acrylic-based adhesives for general purposes, rubber-based adhesives for quick stick and repositionability, and high-performance adhesives designed for extreme temperatures or challenging substrates.

Performance Characteristics of Metal Adhesive Labels

-

Durability:

The choice of metal directly impacts resistance to physical wear, corrosion, chemicals, and environmental factors like UV exposure. Stainless steel and anodized aluminum provide excellent durability. -

Adhesion Strength:

High-quality adhesives guarantee that labels remain firmly attached without peeling, even on rough or curved surfaces. Adhesion performance is tested against factors like temperature, humidity, and surface texture. -

Temperature Resistance:

Metal adhesive labels are designed to withstand a wide temperature range—from sub-zero conditions to high heat environments—without losing adhesion or degrading. -

Chemical Resistance:

Coatings and materials ensure resistance to oils, solvents, acids, and other chemicals that could otherwise damage the label or adhesive. -

Printability and Marking:

Metals like aluminum and stainless steel can be laser-etched, engraved, or printed with high precision to produce barcodes, serial numbers, logos, and detailed graphics that remain clear and durable. -

Flexibility and Thickness:

Metal adhesive labels balance flexibility to conform to surfaces and sufficient thickness to resist tearing or deformation.

Conclusion

Selecting the appropriate materials and understanding their performance characteristics is key to maximizing the effectiveness of metal adhesive labels. Whether you need lightweight aluminum labels for general use or heavy-duty stainless steel labels for harsh environments, the right combination of metal and adhesive ensures durable, reliable, and professional identification solutions.